Supply chains have transformed dramatically, even compared to five years ago. Demands fluctuate overnight, compliance requirements accumulate, and a disruption can spread across regions within hours. Manual updates and spreadsheets are no longer sufficient. Supply chain professionals require tools that will offer real-time visibility of risk, speed up decision-making, and ensure partners and teams are on the same page.

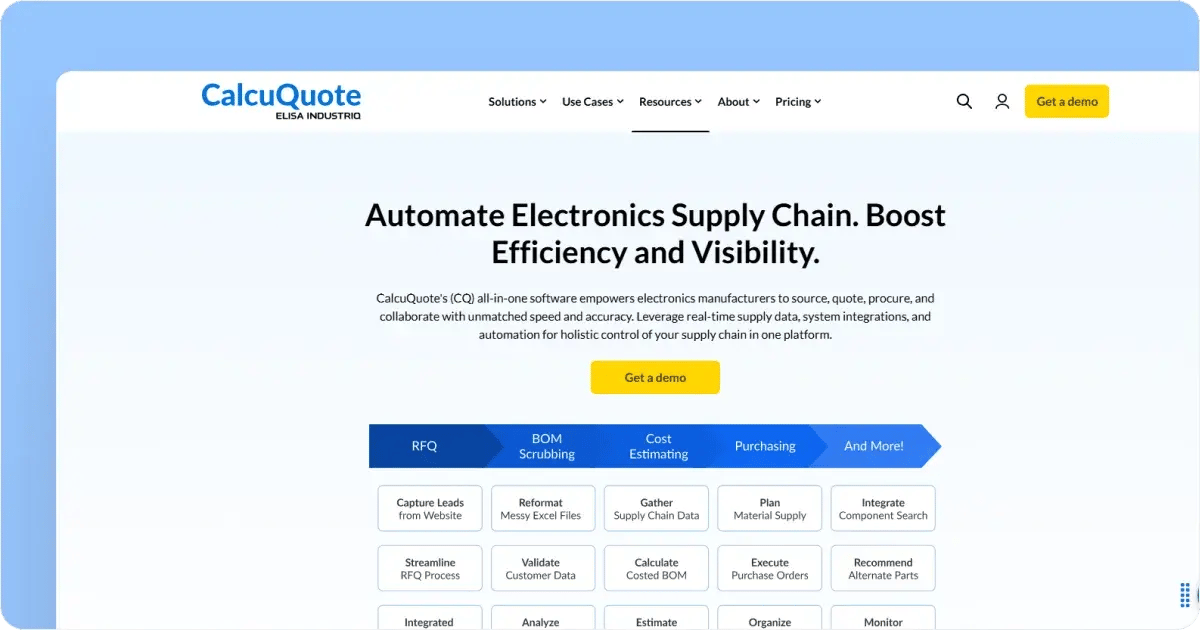

Tools like CalcuQuote are already showing how modern supply chain software can streamline what was previously time-consuming. And it is not the only one.

This article will discuss some of the top supply chain tools every professional should be familiar with in 2025, including planning platforms, risk management systems, and more, so you can decide which ones are best suited to your business.

Quick Overview of the Best Supply Chain Tools in 2025

Before going into details, here’s a quick overview of the tools we’ll cover and what makes them stand out:

.webp?width=1200&height=877&name=Tabela%20(1).webp)

1. CalcuQuote

CalcuQuote is designed to meet the challenges of the current electronics supply chains. All the processes, including quoting and sourcing, purchasing, and supplier collaboration, occur in a single connected platform. Teams can access component data in real-time, integrate with the systems they already have, and create workflows that reduce the amount of manual work. CalcuQuote has been serving hundreds of electronics manufacturing services (EMS) providers, original equipment manufacturers (OEM) and suppliers across the globe since it launched in 2014. Today, it is a part of Elisa IndustrIQ, an industrial software division of Elisa Corporation.

Highlights

- Bills of Material (BOM) intake and normalization: Normalize messy part data and map to specific manufacturer part numbers (MPNs).

- Live component intelligence: See the current pricing, availability, lead times, and lifecycle status using supplier APIs.

- Request for quote (RFQ) management: Build RFQs, compare the responses side-by-side, and apply your contract-pricing rules.

- Supplier collaboration: Provide suppliers with a single portal to receive and respond to requests, eliminating email clutter.

- Smart purchasing: Build and follow purchase orders (PO), handle alternates, and synchronize awards to your ERP, MES, and CRM.

- BOM Health and risk visibility: Find out which parts are obsolete and at risk, and have vetted alternatives.

- Alerts and search: Set watchlists on critical parts and be notified when inventory is low.

- Reporting and integrations: Dashboards and open APIs/connectors ensure that leadership is informed and systems are in sync.

Summary: Based on customer case studies, CalcuQuote customers report up to 80% less time in quoting, more clarity of risk and easier handoff between quote and buy.

Unlike generic supply chain tools, CalcuQuote was built specifically for EMS and electronics workflows.

2. Octopart

Octopart is a widely adopted parts‑search and component discovery engine in the electronics space. It aggregates data (specs, prices, stock) from many manufacturers and distributors into a unified interface.

Highlights

- Its BOM Tool allows engineers and procurement teams to upload bills of materials, normalize part numbers, flag issues, suggest alternates, and see real‑time availability and life cycle status (active, obsolete, etc.).

- In 2025, Octopart continues to compete strongly in the parts search domain, citing a database of over 83 million parts.

- It provides high coverage of parts, fast search, useful for early design / sourcing stages (part discovery, alternate parts, BOM vetting).

Summary: Octopart is a practical parts search engine used by engineers and procurement teams to check specifications, pricing, and stock across global distributors in one place. It’s not built for quoting or ERP management, but it’s highly useful for quick component visibility and early sourcing work.

3. Cetec ERP

Cetec ERP is a cloud ERP platform built for manufacturing and assembly environments, including electronics, wire harness, cable, etc.

Highlights

- It supports high‑mix / low‑volume workflows, BOM estimation, order quoting, shop floor control, traceability, quality management, and deep supply chain for procurement.

- In the EMS / PCBA context, Cetec ERP explicitly integrates with CalcuQuote to streamline quoting workflows and manage procurement & BOM import.

- Cetec’s features for electronics include alternate part substitutions, revision management, unit‑of‑measure conversions, reel (SMT) inventory, waste/scrap tracking, and lot/serial traceability.

- It is a full ERP + MRP + QC + shop floor system with electronics‑friendly features. For mid‑sized electronics manufacturers, it offers a good balance of capability and cost.

Summary: As with most ERP systems, adopting Cetec requires thoughtful implementation and change management. However, its integration with platforms like CalcuQuote helps simplify the process by automating BOM transfers and procurement workflows, reducing manual effort and potential errors.

4. Supplyframe (Design-to-Source Intelligence)

Supplyframe’s flagship offering is Design‑to‑Source Intelligence (DSI), which seeks to “shift left” sourcing decisions into the design phase to reduce risk and cost later.

Highlights

- Their DSI network aggregates billions of signals, tracks part attributes, availability, lifecycles, and market intelligence across components.

- Modules include NPI (new product introduction) analytics, CPQ, sourcing intelligence, commodity forecasting, design/engineering support (e.g., footprint / model libraries).

- For supply chain / sourcing teams, Supplyframe allows proactive risk signals, alternative part suggestions, cost/lead time trend tracking, and collaboration between engineering and procurement.

- Their own surveys in 2025 highlight that digital maturity in design‑to‑source remains uneven, and many electronics companies are still catching up.

- It excels at bridging design and supply, enabling smarter sourcing earlier in the lifecycle. Risk forecasting and intelligence is a differentiator.

Summary: Supplyframe is best suited for teams that prioritize connecting design data with sourcing intelligence to improve visibility and decision-making early in the product lifecycle. It’s not intended to manage routine production operations but rather to support strategic planning, supplier coordination, and cost optimization before manufacturing begins.

5. Oracle Fusion Cloud Supply Chain and Manufacturing (SCM)

Oracle has revamped its complete supply chain suite to fit the requirements of the cloud era and offers a genuinely cloud-native platform that can support demand planning and logistics, manufacturing, and product lifecycle management. It is unique in terms of the high-end features such as predictive maintenance and Internet of Things (IoT) integration, which enable manufacturers to track the condition of their equipment and minimize downtimes and maximize their performance.

Highlights

- Cloud-native platform: The platform has quarterly upats ith no downtime.

- IoT and predictive maintenance: Live equipment data can be fed into predictive maintenance systems by the use of IoT, reducing unplanned downtimes.

- End to end visibility: The modules include planning, logistics, manufacturing execution, and global trade compliance

- Proven scale: Oracle has over 164,000 employees worldwide and the scale to support large, multi-tier supply chains.

Summary: Oracle provides a wide range of supply chain and manufacturing capabilities, which can be both beneficial and complex. It scales well for large enterprises, but costs often rise as data volume grows, and implementations can take longer when replacing older or customized legacy systems.

How to Choose the Right Supply Chain Tool

With all these tools, the real problem is not to find one but to find one that can really help you in your day-to-day challenges. The most effective method of making this choice is to compare features with your priorities and workflows. The main points to remember are:

- Ease of use: The tool must not make the process difficult but must make it easy. Platforms that your team can learn in a short period without having to be trained.

- Real-time visibility: Delays happen when data isn’t updated in real-time. Select software that will be able to import real-time pricing, inventory, orders and logistics.

- Effective BOM management: In electronics, in particular, the capability to clean, standardize and trace BOMs over revisions is a deal breaker.

- Supplier cooperation: Constant chains of emails and spreadsheets are not an option. Portals and direct integrations with the suppliers make communication more efficient and clear.

- Risk and compliance assistance: Regulations are getting stricter. The appropriate tool must enable you to remain audit-ready with traceability and compliance integrated.

- Scalability: Your supply chain will change. Make sure that the tool can be scaled to support your future requirements in terms of sites, regions or volumes.

- Integration into the current systems: You don’t want silos, so make sure that the tool integrates well with your ERP, CRM and other core systems.

When you compare these benchmarks with your business priorities, the correct decision becomes more obvious. One company might have a priority on predictive risk insights, another on quoting accuracy or supplier visibility. The idea is to select a tool that eliminates the bottlenecks that are currently holding your team back and that will help you work smarter in the future.

The Smarter Way to Quote, Source, and Deliver

CalcuQuote eliminates the guesswork in quoting and sourcing. All the information is in a single location, including BOMs, supplier bids, part data, and purchase orders, so your team spends less time tracking down updates and more time getting work done.

Companies that have implemented CalcuQuote have reduced quoting cycles to days to hours and have gained the visibility to identify supply risks before they become apparent. It has become the preferred system of hundreds of EMS providers and OEMs that require precision and speed in a high-pressure environment.

CalcuQuote is designed to put you in control of a supply chain that matches your business. Request a demo and check how it works in practice.

![8 Luminovo Alternatives to Consider in 2025 [Comparison List]](https://www.calcuquote.com/hs-fs/hubfs/Cover-1.webp?height=500&name=Cover-1.webp)